Understanding Excavator Hydraulic Parts: A Comprehensive Guide

In the world of heavy machinery, excavator hydraulic parts play a pivotal role in ensuring that equipment operates smoothly and efficiently. Excavators are essential for construction, mining, and various other industries, making it crucial to understand their hydraulic systems. This article will delve deep into the intricacies of excavator hydraulic parts, offering insights into their functionality, maintenance, and purchasing options from reputable suppliers like Shop Hydraulic America.

What Are Excavator Hydraulic Parts?

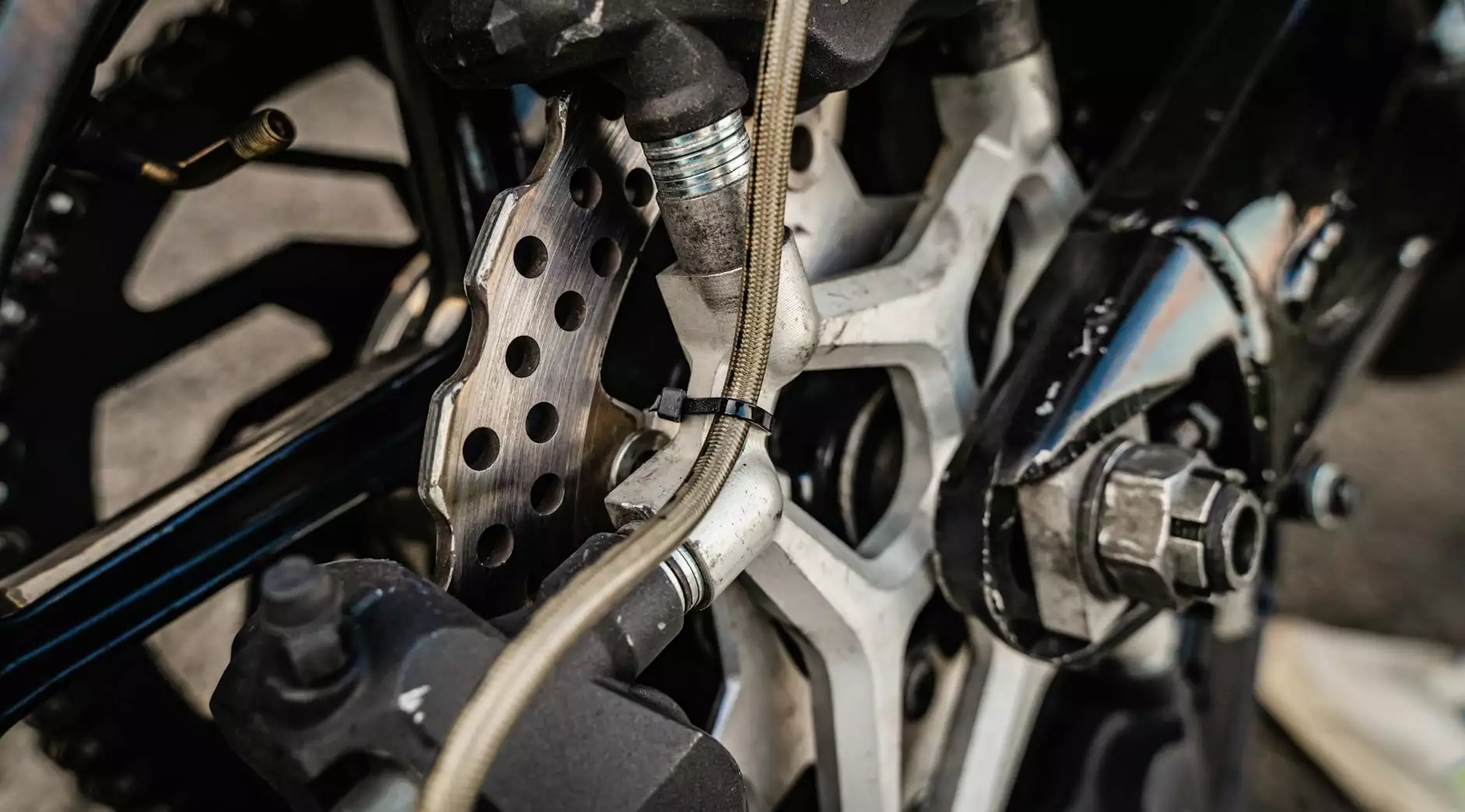

Excavator hydraulic parts are components that facilitate the movement and control of an excavator’s hydraulic system. These parts work together to convert hydraulic fluid pressure into mechanical force, allowing excavators to perform lifting, digging, and moving operations efficiently. Key components include:

- Hydraulic Pumps: These convert mechanical energy into hydraulic energy by drawing fluid from the reservoir and forcing it through the system.

- Hydraulic Cylinders: The cylinders convert hydraulic pressure into linear motion, enabling the movement of the boom, arm, and bucket.

- Hydraulic Hoses: Essential for transporting hydraulic fluid between components, these hoses must be durable and resistant to high pressure.

- Valves: These regulate the flow and direction of hydraulic fluid, allowing for precise control of the excavator's movements.

- Filters: Hydraulic filters are critical for maintaining the cleanliness of the hydraulic fluid, preventing contaminants from damaging other parts.

Types of Hydraulic Systems in Excavators

Excavators may feature different types of hydraulic systems, including:

- Open-Center Hydraulic Systems: In these systems, hydraulic fluid flows through the system continuously, even when not in use. They are characterized by simpler design but less efficiency.

- Closed-Center Hydraulic Systems: These systems only circulate fluid when needed, improving efficiency and performance for various tasks.

- Variable Displacement Pumps: Variable displacement pumps adapt the flow of hydraulic fluid based on demand, optimizing power and fuel consumption.

How Excavator Hydraulic Parts Function Together

The smooth operation of excavator hydraulic parts relies on the synergy of each component:

When the operator inputs a command, hydraulic fluid is pumped from the reservoir by the hydraulic pump through the valves. The valves open to direct fluid into the appropriate hydraulic cylinders for the boom, arm, or bucket. As the fluid fills these cylinders, the pressure builds, causing the cylinders to extend or retract, executing the desired movement.

Importance of Quality Excavator Hydraulic Parts

Investing in high-quality excavator hydraulic parts is essential for several reasons:

- Durability: Quality parts are designed to withstand high pressure and heavy use, reducing the risk of breakage and maintenance costs.

- Performance: Superior parts improve hydraulic efficiency, leading to better fuel consumption and operational performance.

- Safety: Using reliable parts minimizes the risk of hydraulic failure, ensuring the safety of operators and onsite personnel.

Maintenance Tips for Excavator Hydraulic Parts

Proper maintenance of excavator hydraulic parts is crucial for maximizing the lifespan and performance of the hydraulics. Here are some essential maintenance tips:

- Regular Inspections: Routinely check hydraulic hoses, cylinders, and fittings for leaks, wear, or damage.

- Fluid Levels: Maintain proper hydraulic fluid levels to ensure efficient operation and to prevent overheating.

- Filter Changes: Replace hydraulic filters based on manufacturer recommendations to keep contaminants at bay.

- Flush the System: Periodically flush the hydraulic system to remove sludge and particles that could clog or damage components.

- Monitor Performance: Pay attention to operating performance; any changes in responsiveness could indicate a problem with the hydraulic parts.

Choosing the Right Excavator Hydraulic Parts Supplier

When it comes to sourcing excavator hydraulic parts, selecting the right supplier is crucial. Here’s what to consider:

- Reputation: Choose a supplier known for quality and reliability. Check reviews and testimonials from other customers.

- Product Range: A good supplier should offer a comprehensive range of parts for various excavator brands and models.

- Customer Service: Look for suppliers that provide excellent customer support, including pre-sales assistance and after-sales service.

- Competitive Pricing: While cost is important, prioritize quality over price to ensure lasting performance.

Cost Considerations for Excavator Hydraulic Parts

The cost of excavator hydraulic parts can vary significantly based on several factors:

- Type of Part: OEM (Original Equipment Manufacturer) parts tend to be more expensive than aftermarket parts, but their quality is generally higher.

- Brand: Well-known brands usually come with a premium price tag but often offer better performance and longevity.

- Market Demand: Prices can fluctuate based on demand and availability, especially for specific models or types of parts.

- Bulk Purchases: Some suppliers offer discounts on bulk purchases, which can be advantageous for businesses needing multiple parts.

Conclusion

Understanding excavator hydraulic parts is essential for anyone involved in the construction or heavy machinery industries. From knowing the types of hydraulic systems to maintaining your equipment, every aspect plays a vital role in maintaining operational efficiency. By sourcing high-quality parts and adhering to rigorous maintenance protocols, you can ensure your excavator remains a dependable workhorse on your job sites.

For top-quality excavator hydraulic parts and excellent customer service, consider visiting Shop Hydraulic America. Their extensive range of products and commitment to quality ensures you will find the right components to keep your machinery running smoothly.