Understanding the Impact of China CNC Machining Parts on Modern Manufacturing

The evolution of manufacturing has seen a significant transformation with the advent of CNC machining (Computer Numerical Control machining). Among the key players in this domain is China, renowned for its advanced manufacturing capabilities and cost-effective solutions. This article delves into the core aspects of China CNC machining parts and how they are shaping the landscape of metal fabrication.

The Rise of CNC Machining in China

In recent years, China has emerged as a global leader in CNC machining. The reasons for this rise are manifold:

- Advanced Technology: China has invested heavily in modern machining technology, ensuring high precision and efficiency.

- Skilled Workforce: A large pool of skilled labor helps in the production of high-quality CNC machined parts.

- Cost Efficiency: Competitive labor costs make China an attractive option for businesses worldwide.

- Infrastructure Development: Robust manufacturing infrastructure supports rapid production and delivery.

What are CNC Machining Parts?

CNC machining parts refer to components produced using automated machinery that uses computer-controlled tools. This process allows for the creation of highly detailed and complex shapes that would be difficult or impossible to achieve through traditional manufacturing methods. Key characteristics of CNC machining parts include:

- High Precision: Tolerance levels can reach as low as ±0.001 inches.

- Repeatability: CNC machines can produce thousands of identical parts without variance.

- Complex Geometries: Parts can be designed with intricate designs that are uniform and precise.

- Material Versatility: Suitable for a wide range of materials, including metals, plastics, and composites.

Advantages of Using China CNC Machining Parts

When businesses opt for China CNC machining parts, they can expect numerous advantages that can enhance their operational capabilities:

1. Cost-Effectiveness

One of the primary advantages of sourcing machining parts from China is the cost savings associated with lower manufacturing expenses. This allows companies to:

- Reduce overall production costs.

- Invest more resources in R&D.

- Offer competitive pricing in their markets.

2. Speed of Production

With advanced technology and an efficient supply chain, manufacturers in China are capable of delivering CNC machining parts at unmatched speed. This rapid turnaround is essential for businesses that need to respond quickly to market demands.

3. Quality Assurance

Many Chinese manufacturers maintain quality assurance protocols that are comparable to global standards. Certifications such as ISO 9001 ensure that the products meet international quality benchmarks.

4. Scalability

Companies can easily scale their production up or down as needed without significant lead times or resource reallocations, ensuring flexibility in operations.

The CNC Machining Process Explained

Understanding how CNC machining works will give manufacturers a better appreciation of the intricacies involved in creating China CNC machining parts.

Step 1: Design Creation

It all begins with creating a design using CAD (Computer-Aided Design) software. Engineers can build 3D models that detail every aspect of the part. This digital representation ensures precision before the manufacturing process even begins.

Step 2: Programming the CNC Machine

Once the design is finalized, it is translated into a format that the CNC machine can interpret. This involves:

- Creating a G-code, which is the language understood by CNC machines.

- Inputting specifications such as speed, feed rate, and tool paths.

Step 3: Machining the Part

The CNC machine begins the machining process by following the programmed instructions. This includes:

- Cutting: Removing material from the workpiece using various tools.

- Drilling: Creating holes with precision.

- Milling: Turning the material to achieve the desired shape.

Step 4: Finishing Touches

After machining, parts may require additional finishing processes to enhance appearance or functionality. This could include:

- Polishing.

- Coating.

- Assembly with other components.

Industries Benefiting from China CNC Machining Parts

The versatility of CNC machining parts makes them invaluable across several industries, including:

1. Automotive Industry

The automotive sector leverages CNC machining for components such as engine blocks, transmission parts, and more, ensuring quality and reliability in performance.

2. Aerospace Sector

In aerospace, precision is non-negotiable. Parts such as brackets, engine mounts, and structural components require the highest levels of accuracy, which CNC machining can provide.

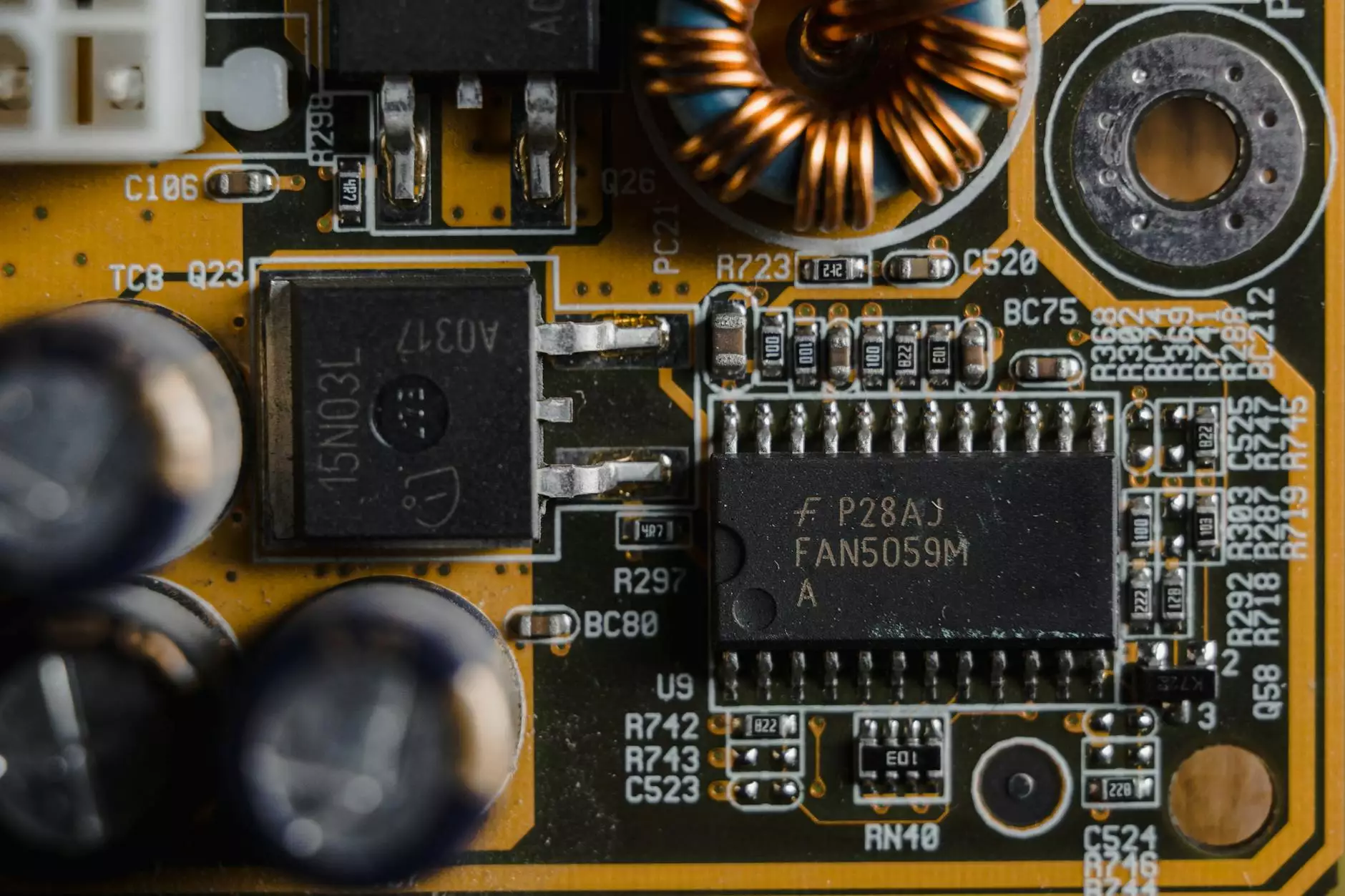

3. Electronics Manufacturing

Manufacturers in the electronics field often require small, intricate components that can be effectively produced through CNC machining. This includes parts for circuit boards and housing casings.

4. Medical Devices

The medical industry relies on CNC machining for the development of surgical instruments and medical implants, where precision directly impacts patient outcomes.

Choosing the Right CNC Machining Partner in China

When sourcing China CNC machining parts, selecting the right partner is crucial for success. Here are key factors to consider:

- Experience and Expertise: Look for manufacturers with years of experience in the field and a strong portfolio of previous work.

- Certifications: Verify that they hold relevant certifications that ensure quality control and adherence to industry standards.

- Communication: Effective communication is essential for ensuring that the specifications are met. Choose a partner that values transparency.

- Post-Production Support: Consider suppliers who provide after-sales support, including returns, repairs, and modifications.

The Future of CNC Machining in China

As technology continues to advance, the future of CNC machining in China looks promising. Key trends that are shaping this future include:

1. Automation and Robotics

The integration of automation and robotics is expected to further enhance efficiency and reduce costs, allowing for more complex operations with minimal human intervention.

2. Additive Manufacturing Integration

The combination of CNC machining with additive manufacturing (3D printing) opens new avenues for producing components with intricate designs that were previously unattainable.

3. Sustainable Practices

As businesses become more environmentally conscious, there’s a growing emphasis on sustainable manufacturing practices, focusing on reducing waste and energy consumption.

Conclusion: The Strategic Advantage of China CNC Machining Parts

In conclusion, China CNC machining parts play an instrumental role in redefining the manufacturing landscape. By leveraging advanced technology, skilled craftsmanship, and cost efficiency, businesses can enhance their productivity, remain competitive, and innovate rapidly. As the industry evolves, companies that adopt CNC machining will be well-positioned to meet the challenges of tomorrow.

If you are considering sourcing China CNC machining parts, explore the offerings at DeepMould.net to connect with manufacturers who can meet your unique needs.